Condenser Heat Load

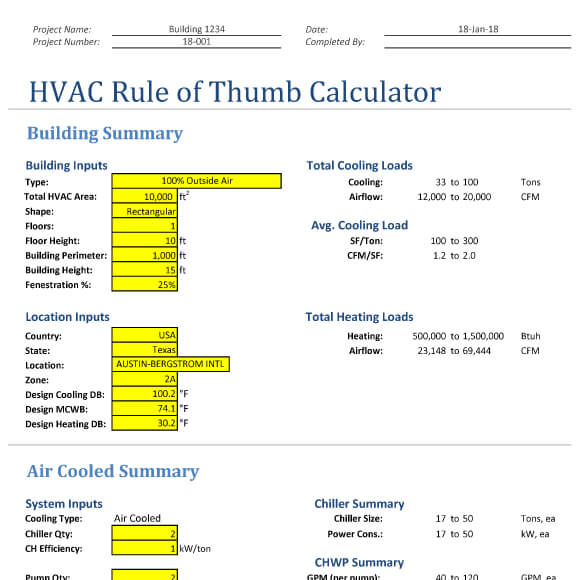

Thermal design calculations of Shell & Tube condensers for horizontal condensers. Condenser Design. (excel, pdf formats supported). Shell and tube heat exchangers are used extensively. For data entry and a shortcut calculation method in Excel to allow an independent. In design, a correction. Evaporator Design Calculations In Excel 1 Formulas and design parameters in Robert Evaporator Design with online calculation sheet. 1.1 Types of Evaporators: 1.2 Steps in calculation of. Thermodynamic Design of Condensers and Evaporators. The designer should verify that the design. Condenser Design Calculation Pdf To Excel. This software can design, horizontal shell side condensers, horizontal tube side condensers, vertical shell side condensers, vertical tube side condensers and reflux condensers. This software application is intended for use by professional and academics in the engineering industry. DO NOT USE THIS METHOD FOR DETAIL DESIGN – ALWAYS CONSULT A REPUTABLE SUPPLIER FOR DETAIL DESIGN Condenser sizing calculation tool Input Results Orientation Heat exchange area m2 Condenser Horizontal Number of tubes Tube length m Tout Tin Cooling fluid Number of passes Water Overall heat exchange coefficient Vapor Steam Condensation at.

Condenser Heat Transfer Calculations

Condenser Heat Load

Condenser Design Calculation

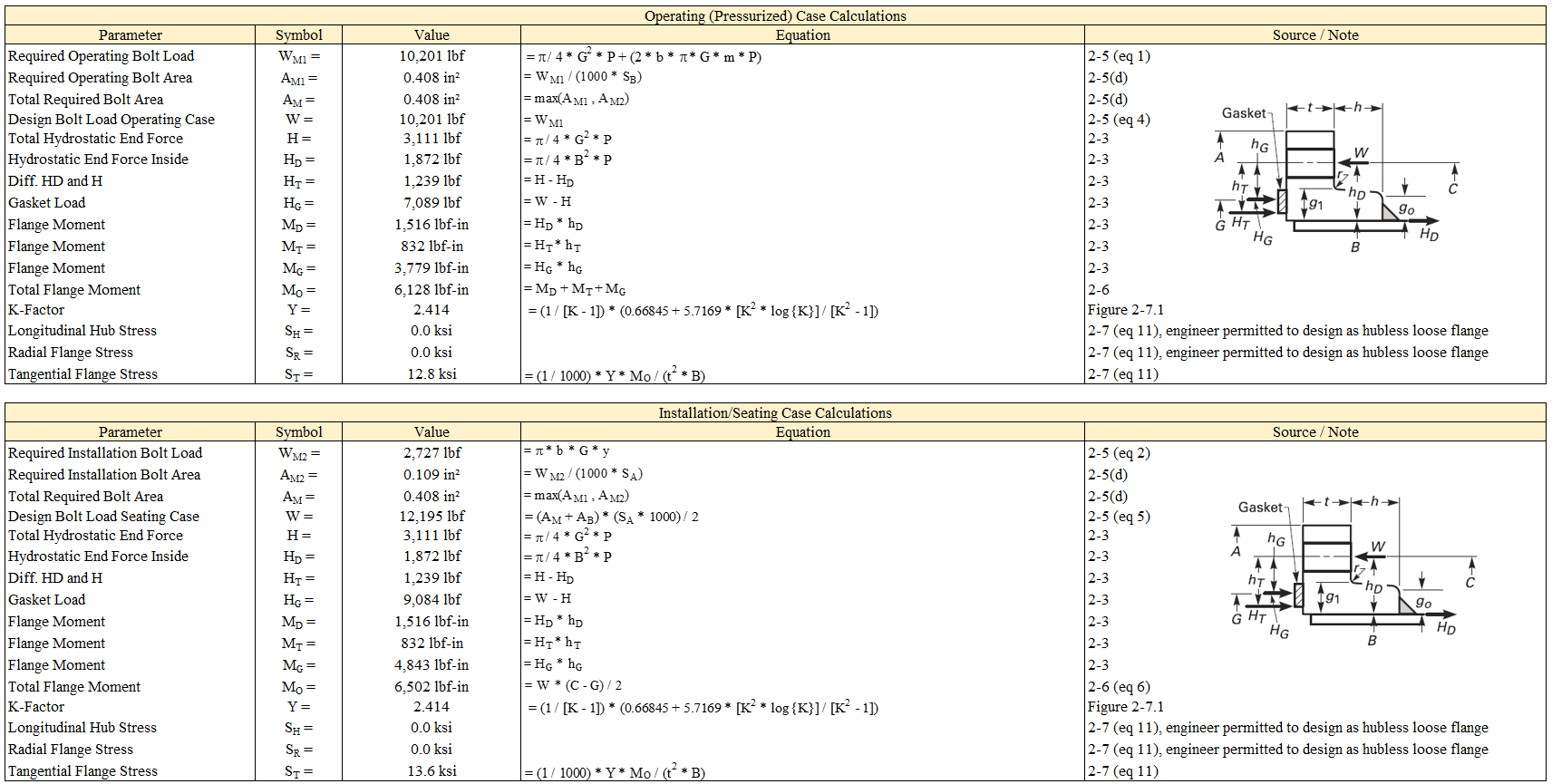

The heat load was calculated by the flow rate times the difference between the enthalpy of vaporization (969.89)and the enthalpy of the condensate (98.56).

My question is why was the heat load calculated as shown above. It seems that the necessary heat load would be the flow rate times the enthalpy of vaporization, which i thought was the energy transfer needed to condense the steam.

Thank You for any help anyone may have.